It has a design service for vehicle companies seeking custom power distribution units that handle between 60 and 1,000V “that are compact, robust and can be flexibly configured”, it said.

“Press-fit technology makes it possible to implement solutions that have proven to be reliable under extreme operating conditions,” according to Wurth. “Low contact resistance leads to high current-carrying capacity and low heat generation.”

It also promotes press-fit as a way to save time in production, and press-fit screw terminals allow distribution units to be reconfigured and maintained.

Yesterday, Ennovi advocated press fit power Ethernet PCB connectors for automotive reliability

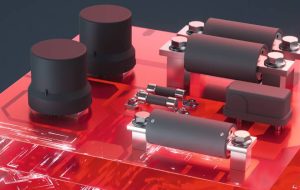

The power distribution housings are corrosion-resistant, sealed and can be shielded, and the internal PCBs can incorporate protection including fuses, pre-charge circuits, battery management components, and monitoring of current, voltage, temperature and insulation.

Use is foreseen handling power between batteries, on-board chargers, inverters, heaters and dc-dc converters.

“Power distributors are one of the few components in the high-voltage electrical system that are developed individually for each vehicle,” said Wurth product manager Ludovic Frelin. “We offer a complete service with electromechanical and electronic design, from concept to series production, hardware development, software development, testing and qualification.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News