Delta has created a 500kW electric vehicle charger for trucks and busses. Called UFC500, it uses silicon carbide power transistors and charges two smaller vehicles simultaneously at up to 250kW each, or one vehicle at 460kW. The exterior design meets IP55 and IK10, and cables are top-mounted to reduce the changes of damage, on a moving arm to extend reach ...

Tag Archives: electric vehicle

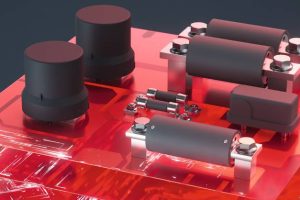

Wurth advocates press-fit PCB connections for high-voltage vehicle power distribution

Würth Elektronik is promoting PCBs with press-fit power connectors as the interconnection technology of choice for high-voltage power distribution in mobile machines and commercial vehicles. It has a design service for vehicle companies seeking custom power distribution units that handle between 60 and 1,000V “that are compact, robust and can be flexibly configured”, it said. “Press-fit technology makes it possible ...

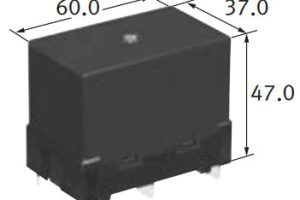

US-compliant relay switches 70A 277V single-phase

Panasonic has launched a series of 70A PCB-mount power relays designed to US standards “The HE-R2A relay series is suited for modern wall box designs, and we are happy that we can offer a UL508-compliant sibling of the HE-R type for European four-phase systems, enabling the consolidation of switching functions onto PCBs with space savings,” said Panasonic product manager Bernd ...

Temperature sensing tape runs through vehicle Li-ion battery packs

Littelfuse has invented an AEC-Q200-qualified temperature monitoring tape for electric vehicle batteries. Branded TTape, it detects local over-heating via thermally sensitive spots spaced along its length, all connected in series. The spots are positive temperature coefficient thermistors. “Distinguishing itself from NTCs [negative temperature coefficient thermistors], the profound advantage of localised cell overheating detection ensures quicker alerts to the battery management ...

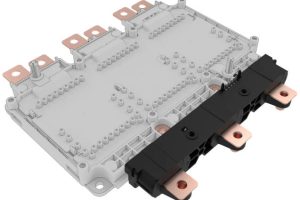

Triple current sensor for 800V traction inverters up to 1MW

LEM has announced three-phase current sensors that fit silicon carbide power modules typically used in 800V vehicle traction inverters. “Developers of automotive traction inverters are increasingly using three-phase power modules such as Hybridpack Drive from Infineon, Acepak Drive from ST Microelectronics, SSDC from ON Semi, and others such as Starpower and CRRC,” according to LEM. “The current sensor offers current ...

Hyundai and Kia sign up for Infineon silicon carbide

Hyundai and Kia have signed supply agreement for SiC and silicon power semiconductors from Infineon, lasting to 2030, for which Infineon which will build and reserve manufacturing capacity for SiC and Si power modules and chips. “This partnership empowers Hyundai Motor and Kia to stabilise its semiconductor supply,” said Hyundai head of strategy Heung Soo Kim. “Infineon stands as a valued ...

Steer-by-wire module for bespoke and low-volume vehicles

Cambridge-based Titan has announced a steer-by-wire system for vehicles “from electric hypercars to automated trucks which has been designed to meet demand from lower-volume manufacturers who need a bespoke system”, it said. The 48V electric motor that operates the steering rack was developed in-house along with the rest of the mechanical system and the control unit. All of it is ...

Battery Show: Bel shrinks 4kW vehicle accessory dc-dc converter in second generation

Bel Fuse has released a second generation of its kW-class dc-dc converter for powering accessories from an electric or hybrid vehicle battery. Rated at 4kW, 700DNG40-24-8 is smaller and, at 450 to 900Vdc, operates over a wider input voltage range than its 700DNC40-24-8G predecessor. Size is 285 x 55 x 355mm including protrusions, and it weighs 4.5kg. The galvanically-isolated output ...

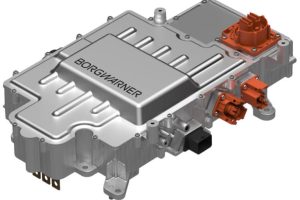

BorgWarner gets SiC power from ST as well as Onsemi

Only a few weeks ago Onsemi announced that its silicon carbide power transistors are to be used in BorgWarner Viper electric vehicle traction inverters, and now STMicroelectronics has revealed something similar. “STMicroelectronics will supply BorgWarner with third-generation 750V silicon carbide power mosfet die for their proprietary Viper-based power module,” according to ST. “This power module is used in BorgWarner’s traction ...

Clever Hyundai borrows components for its 400V to 800V inverter

Hyundai uses 800V batteries in some of its electric vehicles, but not all road-side chargers have an 800V option, so some sort of 400V to 800V inverter is required in the vehicle. And for fast charging, that has to handle a heck of a lot of current – maybe 200A. Rather than have a separate box, and noting that vehicle ...

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News