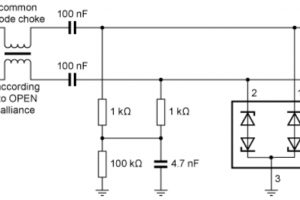

To manage this, the growth in hyperscale computing solutions and high-speed 5G telecom systems continues unabated. At the same time operators are seeking to squeeze higher performance levels and improved efficiency into a decreasing form-factor, fueling the transition from conventional 12 V server racks to 48 V backplane architectures. Supporting this move, Nexperia’s latest 80 V and 100 V ASFETs for Hotswap and Soft Start in LFPAK56E set a new benchmark in power density.

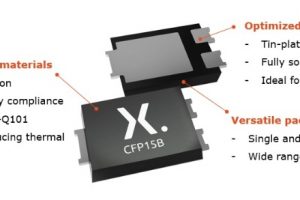

Hyperscale computing often relies on massively scalable server architectures and virtual networking. Hotswap functionality remains a key feature to ensure that equipment remains always connected, 24/7. However, the level of performance required in switching efficiency and strong Safe Operating Area (SOA) was previously only achievable in a D2PAK package (160 mm2). Nexperia’s new ASFETs means designers have access to the low RDS(on) and strong linear-mode performance required in a 30 mm2 LFPAK56E package. Enabling an 80% footprint saving, and 75% height saving compared to D2PAK.

LFPAK56E delivers an 80% reduction in footprint compared to D2PAK

Enhanced SOA MOSFETs

Nexperia’s recent launch of NextPower 80 V and 100 V premium MOSFETs delivered significantly improved RDS(on) in an industry compatible 5×6 mm footprint. Adding the proprietary ‘enhanced SOA process’ gives an additional 3-to-4 times SOA boost, making these new ASFETs ideally suited for linear-mode switching applications such as hotswap and soft-start, efuse and battery management.

For 48 V telecom systems that are typically more exposed to the elements, then 100 V devices offer the best resistance to transients, lightning strikes and cable inductance. In contrast, computing servers and industrial applications are typically well protected against the elements so 80 V devices offer lower RDS(on) and improved efficiency due to lower I2R losses.

For those requiring even lower RDS(on) and stronger SOA, Nexperia is also sampling the first devices in the LFPAK88 package ( and PSMN1R9-80SSE). Targeting release towards the end of 2022, these LFPAK88 devices will take RDS(on) as low as 1.9 mΩ. With a footprint of 64 mm2, compared to existing D2PAK types they also achieve approximately 50% lower RDS(on) in a PCB footprint that is around 60% smaller.

| Type | Package | PCB footprint (mm2) | RDS (on) (mΩ) | SOA @50V @100mS | SOA @50V @10mS |

| PSMN4R8-100BSE | D2PAK | 160 | 4.8 | 3 A | 10 A |

| PSMN4R8-100YSE | LFPAK56E | 30 | 4.8 | 4.5 A | 8 A |

| PSMN4R2-80YSE | LFPAK56E | 30 | 4.2 | 4.5 A | 8 A |

Staying cool

SOA performance is determined by thermal stability and typically a MOSFET’s SOA curve is quoted on the datasheet at 25 °C. If the PCB/ambient temperature exceeds this temperature then design engineers must de-rate the SOA curve accordingly. Failure to de-rate can result in unwanted application failures. But the de-rating process is conservative, so de-rating for high temperature can result in a significant loss in actual SOA performance compared to the datasheet graph.

Another unique benefit of Nexperia’s enhanced SOA technology is that SOA performance, and thermal stability, is greatly improved at higher temperatures. Significantly reducing the level of de-rating required when operating beyond 25 °C. In addition, Nexperia has fully characterized SOA for every ASFET type. SOA graphs at 25 °C and at 125 °C are provided on the datasheet for all enhanced SOA types. Allowing design engineers to fully exploit the superior hot-performance while also removing the need to manually de-rate the SOA curve in many applications.

Dependable performance

Nexperia’s 100 V enhanced SOA technology is widely used to manage inrush current in telecom and PoE (Power-over-Ethernet) applications. With over 200 million pieces shipped to date from our enhanced SOA portfolio, design engineers can be confident that are choosing the best performance & quality. So check out our to discover the performance gains and space savings you can make.

About the author

Mike Becker’s passion for power electronics started while developing industrial high-power motor drives at Rolls Royce & Bentley Motors where he helped develop their first concept vehicle using CAN bus, microprocessors and MOSFETs instead of heavyweight electro-mechanical systems. At GenRad, he developed innovative automotive diagnostic solutions, and through participation on ISO & SAE committees helped to co-develop the standardised EOBD diagnostic connector – which is now deployed on millions of vehicles worldwide. As Product & Marketing Manager at Nexperia, Mike uses his deep understanding of electronic applications to develop and deploy innovative and differentiated technologies such as NextPower 100 V and the LFPAK package. Despite this successful and interesting career, Mike still dreams about winning the lottery and sailing around the world on a luxury yacht.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News