One company overcoming these design challenges is Recom — an Austrian manufacturer of AC/DC power supplies and DC/DC. For a recent project, Recom wanted to develop a power supply which was primarily intended for medical applications. The goal was to create a solution which had double the power density of the company’s previous model without sacrificing safety, reliability, efficiency, or performance. To get there, the development team had to use the latest advances in switching controllers, topologies and components — and turned to Nexperia for help.

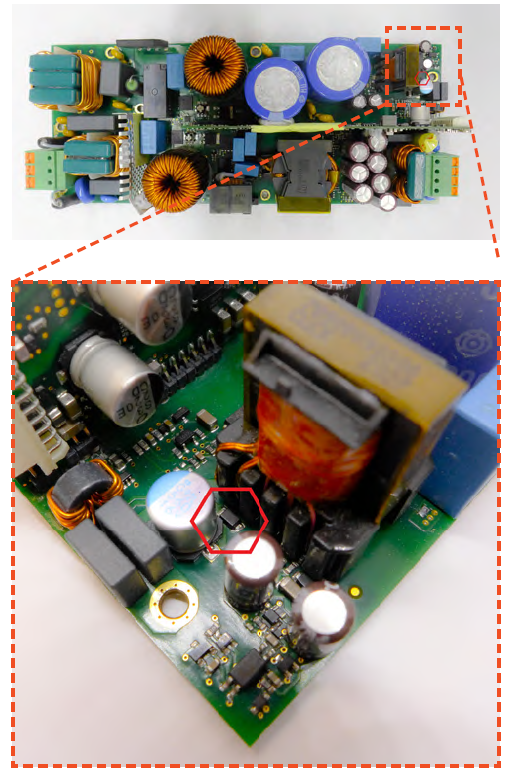

RACM1200-V, 1200 W AC power supply by Recom Power

Strict medical requirements set the bar

The new Recom RACM1200-V power supply had to meet the strict requirements of IEC60601-1, a series of technical standards for the safety and performance of medical electrical equipment. These requirements include maintaining safety with the appropriate creepage and clearance distances on the PCB, while also keeping power dissipation at a minimum.

The product parameters specified that the AC/DC power supply needed to deliver a peak output power of 1.2 kW. As well as the main output, it was necessary to have two auxiliary outputs: a 12 V/1 A supply to power an optional cooling fan, and an always-on 5 V/1 A output for control and monitoring purposes. Due to the compact size of the overall design, overheating was a significant risk.

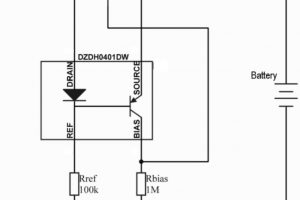

At first, Recom tried fitting planar Schottky rectifiers for both the DC/DC and AC/DC auxiliary power converters, but overheating was still a challenge (particularly under full load conditions). To solve this problem, Recom selected Trench Schottky diodes. The trench concept reduces leakage currents, thus increasing thermal stability. It also improves switching performance compared to planar Schottky diodes.

High density PCB of RACM1200-V including PMEG100T20ELR

Delivering high efficiency, switching performance and thermal stability

“We looked at products from different Trench Schottky diode suppliers”, explains Steve Roberts, Innovation Manager at Recom. “After giving each of them considerable scrutiny, we came to the conclusion that Nexperia’s components were the best choice. These offered enhanced thermal performance and a larger SOA, which would both be critical features if we were to meet the standards relating to medical applications. Additionally, the low profile of these products was another key advantage.”

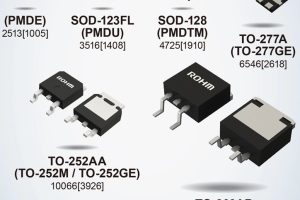

Provided in a small and flat surface-mounted package, Nexperia Trench Schottky diodes can handle a maximum forward current of 2 A, with a maximum reverse voltage of 100 V. They have a very low leakage current, a low forward voltage drop as well as a very low reverse recovery charge (Qrr) that is typically only 8.5 nC. These characteristics proved pivotal in minimizing the rectifier losses in Recom’s design.

Trench Schottky rectifiers offer industry-leading switching behavior and low Qrr

Power supply with high power density and fan-less operation

By leveraging Nexperia’s copper clip-bonded FlatPower (CFP) technology, which helps improve the heat conduction from the package to the board, Recom could design a PCB with low thermal impedance paths that would dissipate the heat generated, without needing to use gap pads or additional heat sinks for the power diodes. The Trench Schottky configuration also means that the thermal stability of the diodes is improved, with a wide safe operating area (SOA).

Through working with Nexperia on this project, Recom was able to launch a compact, highly efficient baseplate-cooled power supply. Now available on the market, the RACM1200-V can deliver a continuous power output of 1 kW with the baseplate held to 80 °C. Peak output of up to 1.2 kW is available for up to 10 s, or continuously with airflow. It achieves a peak efficiency of typically 95 %.

The full case study is available to download here.

About the author

Following his PhD in Theoretical Physics from the University of Basel, Switzerland and post-doctoral research at University of Regensburg, Jan Fischer joined the Hamburg team (NXP) in 2011 as a Development Engineer. Building up almost six years experience in that role, he became the Product Manager for Schottky and SiGe Rectifiers.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News