This unstoppable trend is having a dramatic effect on the way that cars are designed and built. Electronic components and software are expected to make up 35 per cent of the bill of materials for a typical premium model by 2025, as cars move from a reliance on mechanical systems to become ‘computers on wheels’.

Drive cycles are changing, too. Electric cars of the future will play a crucial role in the emergence of shared mobility – with ride-hailing and car-sharing providing more flexible transport options. This trend will result in shorter but more regular journeys, with higher reliability needed for increased operating times.

Reliability of electronic components

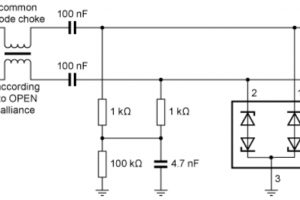

The challenge for automotive engineers is to design electronic systems and components that can survive the rigours of this new operational environment. Tier 1 suppliers are increasingly looking to introduce more stringent stress test qualifications to ensure the performance and reliability of semiconductor packages. Previously, AEC-Q101 was seen as the gold standard for stress-test-driven requirements and conditions for discrete electronic components. Now automotive suppliers are also implementing testing such as Board Level Reliability (BLR) to evaluate the robustness of semiconductor packages once soldered to the printed circuit board.

But what does this requirement for new levels of robustness mean for semiconductor suppliers? Here at Nexperia, our surface-mount CFP15B clip-bond FlatPower package has just passed BLR testing at a leading tier 1 supplier for the first time. This process meant demonstrating exceptional ruggedness and extended operation times under the harshest operating conditions.

In this specific case, CFP15B was being assessed for use in an engine control unit. As such, BLR verification showed that it exceeded twice the level of reliability performance that would be expected in accordance with AEC-Q101. Meanwhile, power temperature cycles, combining temperature cycling and intermittent operating life tests, saw the device achieve a qualification of 2,600 cycles.

CFP features and benefits

Design innovation and high-quality materials

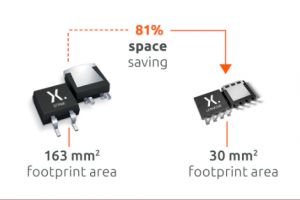

These performance characteristics are made possible by design innovation and the use of the highest-quality materials. CFP15B’s thermal resistance is reduced by featuring a solid copper clip. This optimizes the transfer of heat into the PCB, allowing small PCB designs. The compact and ultra-thin device is up to 60 per cent smaller than DPAK and SMx packages, with no compromise on thermal behaviour. The small sizing presents automotive design engineers with space-saving options and therefore increases design flexibility.

It also provides zero delamination in the areas such as those around the leads, die and clip, eliminating moisture ingress and increasing performance reliability. In addition, the optimized lead form of CFP15B ensures a very uniform solder joint formation on the PCB, allowing maximum flexibility in automated optical inspection (AOI).

The device package is used by different power diode technologies such as Nexperia’s Schottky or recovery rectifiers but can also be extended to Silicon Germanium power diodes or bipolar transistors. It offers significant product diversity, covering single/dual configuration and between 4-20 A, simplifying board design.

The future of electronic component reliability

So, we can see that the automotive sector’s transformation is driving significant change in the supply chain. The more electric and connected cars of the future will feature an ever-increasing application of power electronics, not just for the main propulsion motor control and battery management system, but also for sensors, networking, communications systems, and satellite navigation. In many cases, the demand for high robustness and high-power packages will result in quality levels moving well beyond existing standards such as AEC-Q101.

Nexperia stands ready to support this exciting journey of digital transformation in the automotive industry. We provide proven and future-proofed packages that are rugged, space-saving, versatile, and suitable for high-reliability applications. We also offer tier 1s the opportunity to maximise efficiencies within their operations by consolidating the supply chain by focussing on fewer premium suppliers.

In short, Nexperia represents a trusted and dependable partner for automotive organisations that are embarking on a more electric and connected future.

About the author

Guido Söhrn joined the Hamburg team (Philips) in 2005 as a Product Quality Engineer. Building up almost thirteen years experience in that role, he became the Product Manager for Recovery Rectifiers in 2018. He has been involved in the recovery rectifier development in Hamburg from the very beginning and gained significant experience in clip bond technology during this period.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News

Planned obsolescence is fraud. The auto industry mastered planned obsolescence. Then the Japanese sold quality four cylinder engines with as much power as a push rod V8, >200,000 mile endurance, and inexpensive replacement engines. Electronics have restored the fine art of planned obsolescence.