One of the heaviest sub-systems in most vehicles, wiring harnesses can weigh in at around 150lbs, creating a major headache for designers. Given the fact that a shift to wireless control could reduce total vehicle weight by up to 50 per cent, then it’s little wonder that ‘wireless system management’ is at the top of the agenda for every major OEM. Indeed, the move to electric vehicles (EVs) and the understandable obsession with weight reduction, has given the drive to wireless vehicle management even greater urgency in recent years.

One of the heaviest sub-systems in most vehicles, wiring harnesses can weigh in at around 150lbs, creating a major headache for designers. Given the fact that a shift to wireless control could reduce total vehicle weight by up to 50 per cent, then it’s little wonder that ‘wireless system management’ is at the top of the agenda for every major OEM. Indeed, the move to electric vehicles (EVs) and the understandable obsession with weight reduction, has given the drive to wireless vehicle management even greater urgency in recent years.

If the benefits of ditching copper wire are so great, why are we still seeing them in cars rolling off the production line? The truth is, achieving stable RF comms systems in vehicles is not just a question of ‘plug and play’. Things are a lot more complex once you lift the bonnet.

Hurdles

While an interrupted signal isn’t the end of the world for mobile phone users, when it comes to critical vehicle systems, such as braking or acceleration, there is simply no room for error. Even non-mission critical functions such as headlights or wipers require a reliable signal to ensure consistent functionality. In our discussions with OEMs, this fundamental issue is still considered the central ‘go’ / ‘no-go’ litmus test for wireless technology adoption.

For auto engineers, this involves a simple thought process: getting rid of heavy wiring is great in principle, but if it compromises safety by one iota in practice, we’re not going there.

One of the biggest hurdles facing wireless comms in vehicles is the engine bay. Within this metal tank, which is not more than a metre across, resides a wealth of electrical noise caused by spark plugs (in the case of ICE engines), electric motors and switchgears (where EVs are concerned). For wireless signals, this is a hugely aggressive and constantly changing environment which presents a set of real challenges to antenna designers.

Secondly, the issue of network management poses some real puzzles for electrical engineers. Our work with OEMs demonstrates that separation of wireless signals – for differing levels of control – are a key element. This hierarchy, whereby safety critical operations such as braking and acceleration would take precedence over less crucial functions such as interior lights or electric windows, requires a form of central control while keeping certain wireless signals distinct.

Surprisingly, our feasibility work has also highlighted the problems that humans create in cars when it comes to consistent wireless transmission. At times there might be a single driver in the vehicle (made up of around 70% water), while at others, the car could be full of passengers – all moving within the cabin, creating further potential interference/blocking for signals.

These are just a handful of the key issues we’ve considered during our work with vehicle manufacturers. There are no simple answers to these questions, however we can suggest a constructive way ahead in the dynamic area of wireless design.

Road ahead

A potential solution to the wireless conundrum is meshing technologies, or ‘hopping’ as it’s known in internet parlance. This utilises nodes around the vehicle to shorten the path and make signals less prone to interference. It’s quite complex and not cheap to install but has potential.

Frequency allocation is another consideration that is actively being explored. In principle, lowering the frequency of signal makes penetration much easier throughout the vehicle. However, the sub-gigabyte frequency is a very congested spectrum.

EV pack leader Tesla is looking to integrate power and data cables, in an approach known as power over Ethernet. One big advantage here is that this system is less interference prone. However, where EVs are concerned, the amount of power required is considerable and differences in power requirements could be problematic.

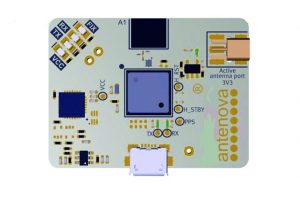

An area of real promise lies in high performance antenna design. We are currently developing next-generation beam steering technology, which effectively points radio waves into specific channels. This approach used to be expensive but is now becoming much more affordable due to design innovation and the adoption of novel materials.

Beam steering of RF signals has the potential to solve many of the problems cited above. Our work in this specialist area proves that we can achieve stable gain in a single direction, far more cost-effectively than was previously possible. It may not be the single, silver bullet where wireless comms is concerned in vehicles, but it’s one of a number of emerging solutions designed to take weight out of vehicles.

Author

With 14 years’ experience in mobile antenna design, Sampson Hu is the core inventor of more than 80 Novocomms patents and has been working on the core technology since 2009. As a founder of Novocomms Limited, he is responsible for the global expansion of the business, its global antenna design and manufacturing operation.

With 14 years’ experience in mobile antenna design, Sampson Hu is the core inventor of more than 80 Novocomms patents and has been working on the core technology since 2009. As a founder of Novocomms Limited, he is responsible for the global expansion of the business, its global antenna design and manufacturing operation.

Sampson Hu also serves the functions of Chief Technology Officer or VP of Engineering and takes full responsibility of successful execution of the company’s business mission through development and the deployment of the company’s technology. He directly helps the technology innovation across the company and leads technology implementation as well as guides the engineers. In the longer term, he also plans for risk and the required growth of the global R&D team.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News