Demand for reed switches has risen significantly in the recent past. This is primarily due to their mechanical structure, which reduces energy consumption to zero when the switch is in a passive state. That is why reed switches are an attractive alternative to Hall-effect sensors for applications in which energy efficiency and low power consumption are key.

Reed and Hall-effect technologies are based on different construction concepts. Both are controlled and activated by means of an external magnetic field whereby electrical current flows through a conductor, with a magnetic field positioned perpendicular to the direction of current. A difference in current is created perpendicular to the electrical and magnetic field planes.

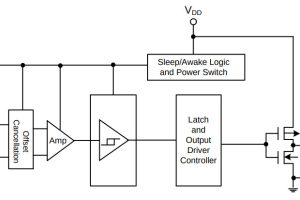

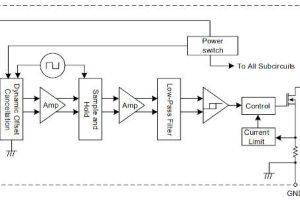

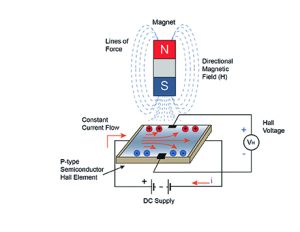

A Hall-effect sensor requires an electrical circuit to operate, which needs power even when the sensor is in a passive state as its construction principle is based on the provision of an output signal (Figure 1).

Figure 1: Hall-effect sensors function due to the Hall effect

(Image: Standex Electronics)

The reed sensor, on the other hand, is a mechanical switch that is only activated by a magnetic field to switch a load. It consists of two ferromagnetic separators that are hermetically sealed in a glass tube with the two separators overlapping. If a magnetic field is applied to the switch, the two blades move towards each other and the switch closes (Figure 2). If it does not receive this pulse, it does not consume any power. This key difference has a variety of consequences for specific applications of both forms of technology.

Figure 2: Reed switch functional principle (Image: Standex Electronics)

Specific uses for each

Demand for reed-based sensors has risen significantly recently against the backdrop of Germany’s energy transition and the requirement to prioritise energy efficiency in the manufacture of end devices. This trend is unlikely to come to an end any time soon as more manufacturers are switching to reed technology, particularly in the case of white goods such as dishwashers and fridges or battery-powered devices.

Sensor manufacturers and customers alike are focusing on minimising the application’s electricity consumption, which can be optimised and/or reduced in accordance with the device’s requirements through the use of reed technology.

The reality is both technologies have their own specific uses. Hall-effect sensors are better suited to high-speed applications in the range of 1kHz and above because this is where the reed contact meets its physical operating boundaries.

For applications with frequencies lower than 1kHz, for example flow meters in white goods, reed switches are recommended. Even though there are not yet any safety standards for reed switches and each application must go through a separate authorisation and safety approval process, they offer one key advantage over Hall-effect sensors: switch hysteresis.

Due to its physical characteristics, the mechanical reed switch features switch hysteresis, which describes the difference between the pull-in and drop-out points of a reed switch. In other words, if a passing magnet reaches a pre-defined pull-in point 5mm away from the reed switch, for example, its blades will close and the reed switch is now active. If the magnet continues to move until reaching a pre-defined drop-out position of 7mm, it will only turn off at this point, for the switch hysteresis to equal 2mm. This feature may be required in certain applications, such as a reed-based water flow meter with a paddle wheel. This switch is resistant against random movements of the water’s waves, which may slightly move the paddle wheel. Manufacturers do not want the switch to be activated, which would cause a measurement to be taken, due to such movements. The water flow must reach a certain rate before the switch is activated and the meter takes a measurement. In other words, if the reed switch moves within its hysteresis, it will not measure units of water. By contrast, Hall-effect sensors are activated or deactivated as soon as the water moves.

Small reed switches

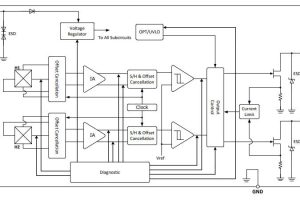

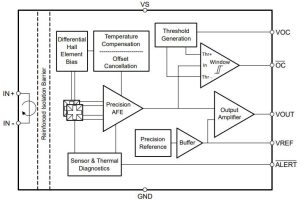

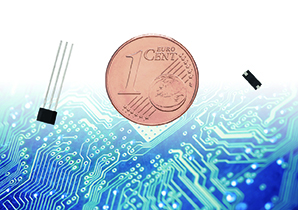

The mechanical structure of a reed switch has an effect on its cost. Reed switches are cheaper to produce than Hall-effect ones, with the latter requiring features such as additional external switches, amplification circuitry, temperature stabilisation, short-circuit protection and electricity consumption. The reed switch may not be able to match the Hall-effect sensor in terms of its minimum size, but what is believed to be the smallest reed switch available with a glass envelope that is just under 4mm long has been developed by Standex Electronics (Figure 3). This enables a compact reed design that can compete with Hall-effect sensors on size.

Figure 3: Reed sensor (right) with a length of 4mm (glass envelope) reaches the dimensions of the Hall-effect sensor (left) (Image: Standex Electronics)

The reed switch is enclosed in a glass envelope that is filled with protective gas, usually nitrogen. This unit is also protected by a stable housing element. The glass and the housing ensure that the reed switch is hermetically sealed from atmospheric influences such as dust, oil, water and chemical substances, which could impair the sensor’s functions. The hermetic seal has the added benefit of protecting the sensor from corrosion.

Reed switches also offer a number of benefits when used in extreme thermal conditions, such as in very hot or cold temperatures. Hall-effect sensors begin to suffer in terms of performance and reliability in such conditions, whereas reed switches function perfectly in temperatures from -65°C to +150°C (Hall-effect sensors operate between -55°C and +125°C).

The reed switch’s mechanical characteristics make it immune against electronic disturbances, meaning that it does not require any protection against electromagnetic discharge (ESD), unlike a Hall-effect sensor. As a result, reed switches have a high level of EMC with neighbouring system-relevant devices. The Hall-effect sensor offers no such EMC because it must emit an output signal and therefore requires a constant supply of power. This means that particular precautions to guard against EMC must be taken to isolate the Hall-effect sensor from neighbouring devices. The most problematic area here is dealing with leakage current; special ESD protection is essential.

The maximum isolation of a reed switch is 1015Ω, which is many times higher than that of a Hall-effect switch. Leakage currents still occur with reed switches. However, these currents are in the fempto-Amp range, which is so insubstantial that it is within the tolerances applied to medical devices. The mechanical principle on which a reed switch is based also allows it to measure tiny voltages. This is due to the low contact resistance of 50mΩ, which is significantly lower than Hall-effect sensors’ contact resistance.

The fundamental range of potential loads that can be switched using a reed switch is huge: it extends from the nanoVolt to kV range, from fempto Amps to Amps and enables frequencies of up to 10GHz. Even the smallest of reed switches is capable of isolating voltages of up to 1,000V. No ESD protection is required for this.

Application-specific configuration

Reed switches are available in a variety of sizes with different Ampere turns and hystereses regarding magnet distance and magnet size. Thanks to the operating principle of the switch these reed parameters can be adapted to application-specific requirements, in other words the special requirements of energy efficiency classes. This puts the Hall-effect sensor at a disadvantage. It can be programmed to compensate for this weakness, but it still lags behind the reed switch when it comes to application-specific configuration.

Hall-effect sensors are more suited to applications with frequencies higher than 1kHz. These include high-speed sensors for measuring revolutions per minute. Due to the lack of switch hysteresis, the Hall-effect sensor offers much higher repeatability when it comes to signal measurement. This also means that it has a longer life cycle. The Hall-effect sensor and its 500 million switch cycles is far superior to reed technology in this respect. However, if the reed switch is required to switch predominantly small loads below 5V, as in the case of meter applications, switch cycles into the billions can be achieved using reed switches.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News