The work, which solves a problem typically associated with such devices made using Group IV materials, could lead to optical components operating at 100GHz.

Optoelectronic components are typically built from III-V semiconductor systems such as GaAs and InP, which have a direct bandgap and display a strong quantum-confined Stark effect (QCSE).

This means that an electric field applied to a structure modifies its optical absorption properties. Depending on how fast this change happens, and how good the contrast is between the two states, it can be used to make an optical shutter.

In the case of Germanium, the lowest energy bandgap is indirect, which makes for a weak QCSE, but there is a direct bandgap at room temperature. The US scientists, at Stanford University and HP Labs in California, used this to create a compact electro-optical modulator.

|

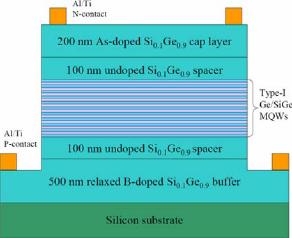

By growing a stack of thin germanium layers on a carefully chosen SiGe layer on a silicon substrate, Professor David Miller and Professor James Harris tuned both the band structure and the optical absorption properties.

Under a reverse bias of 3V, their modulator showed a change in absorption coefficient of 2,800cm-1 at 1438nm. At 4V the coefficient contrast was greater than 3 over the range from 1,443nm to 1,471nm.

Electronics Weekly spoke to Dr Douglas Paul, a SiGe expert at the University of Cambridge, to get some perspective on the research.

“The major breakthrough with the device is that the absorption coefficient of the device can be changed by a large amount just by changing the electric field on the device,” said Paul.

“While this has been achieved in III-V materials, it has not be achieved by a device on a silicon chip. This opens the way to much cheaper modulators for telecoms applications and silicon-based photonics, as they can be produced on some SiGe foundries,” he said.

Earlier this year Intel, one of the sponsors of this research, revealed the first silicon laser, an optically-pumped device. An electrically pumped silicon laser remains something of a Holy Grail.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News

Great effort. It is like improving the performance of the circuit.