These “snake robots” could travel within the systems to access complex parts, says the company. Acknowledging that it sounds like something out of science fiction, or a bad Hollywood movie, the project is considered a potentially viable way to enable repairs that are not currently possible with existing tools.

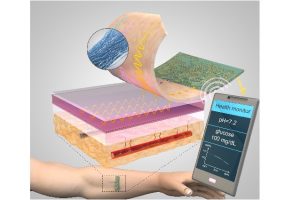

Other ideas include sensors that will send data while the aircraft is flying, to allow the engineers to better predict when the engine will require maintenance.

They are also considering inspection and analysis tools, to inspect parts buried deep within engines while they are being repaired, and advanced automated repair tools that will refresh parts that cannot currently be repaired.

The technologies will be deployed on existing engines, while engineers will also work to ensure they can be applied on future low-carbon engines that will use different materials and components, says the company.

“Our latest engines are quieter and cleaner than ever before, substantially reducing CO2 emissions,” said Dr Ian Mitchell, Chief of Technology – Repair and Services at Rolls-Royce. “This programme will take that one step further by improving how we service our engines, creating technologies which will reduce waste, avoid emissions and minimise disruption, while laying the foundations to service the gas turbine and hybrid-electric engines of the future.”

Some of the innovations could benefit other industries, it hopes. For example, high-tech cameras and algorithms could help identify damage on components in sectors like security and off-shore wind turbines.

Rolls Royce will be working with universities and SMEs including Roke Manor Research, BJR Systems, Clifton Photonics, the Manufacturing Technology Centre, the University of Nottingham, the University of Sheffield, and the University of the West of England.

REINSTATE will be carried out with support from the Aerospace Technology Institute.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News