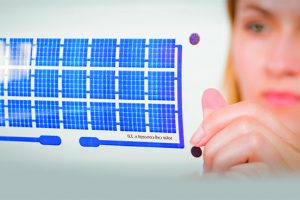

Flexible integrated circuits are thinner than a human hair, yet robust and durable with no rigid connection points.

The ICs are manufactured on a flexible substrate and use a single metal layer antenna to reduce the cost of the tag, resulting in devices that are up to 90% lower in cost than their rigid silicon counterparts.

Cambridge-based PragmatIC has developed ‘FlexICs’ which it has manufactured cost-effectively at its Sedgefield, County Durham facility since May 2018, using the FlexLogIC system, described as a ‘fab in a box’.

Process tools for depositing and patterning materials on to the lightweight flexible substrate are integrated with a robotic wafer‑handling system in a self‑contained clean environment. In this way production lines can be built more quickly than and at a fraction of the cost of setting up a new silicon fab.

Bespoke FlexICs can also be delivered in less than a day, whereas conventional silicon IC production can take over a month, says the company.

The automation of materials handling for throughput and process repeatability, software control of process flows with in-line monitoring combine to ensure high production yield even at sub-micron feature sizes, says Scott White, CEO of PragmatIC.

A quick read

The tags are thin, 10µm labels consisting of an aerial or antenna with a FlexIC that can be read by a smartphone or a reader. The use of single metal layer antennae reduces the cost of the tag by about 80% compared with a silicon tag. At less than 5ms, the read times are almost instantaneous, says Richard Price, CTO, PragmatIC.

“Our mission is connect one trillion everday objects by 2025,” says Price.

At a thickness less than a human hair, the ICs do not add much bulk or height to a product and can also wrap around inconveniently shaped objects such as bottles. Additionally, conventional ICs need to be packaged in plastic for their protection, but this is not needed with FlexICs.

In the rolls of labels there are no ridges or bumps, which makes handling and transportation easier.

The ICs can be used to track and monitor products’ location or environment for shipping and safe consumption.

The reduction in production costs means that products can be individually labelled, to ensure they are kept at the correct temperature, for example, instead of applying a single tag on a box of 12 or more bottles.

FlexICs are already used by labelling and packaging materials company Avery Dennison, RFID company Smartrac and packaging company Talkin’ Things.

Product specifications for PragmatIC’s FlexIC

PragmatIC has introduced the first FlexICs in the ConnectIC family for smart packaging. The PR1101 and PR1102 are designed for use in closed HF RFID systems. They can be embedded into substrates such as paper and plastic for packaging and product tracking.

Operating frequency is 13.56MHz with a typical data rate of 50kbps. The memory capacity is 16-bit and 64-bit low power ROM.

The ConnectIC products are designed for proximity identification, detecting objects when one or more low-cost custom readers are integrated into the system.

Target applications are inventory management, item identification and tracking, supply chain assurance and brand authentication for food and beverage, personal and home care, pharmaceutical and healthcare.

Don’t miss the printed electronics on show at LOPEC in Munich later this month

Next month, LOPEC, the international exhibition and conference for the printed electronics industry takes place in Munich.

The two-day exhibition (20‑21 March) and three‑day conference (19‑21 March) will showcase the latest technology and business developments in printed electronics technology.

The marketplace is diverse, encompassing extremely thin sensors, conductive nano inks, rollable glass as a carrier material, or OLEDs in vehicles and the smart packaging of medicines. The event covers all aspects of printed electronics from research and materials development to production equipment and the latest applications.

The automotive, pharmaceutical and sports industries are major users of printed electronics and many examples of how the technology is being adopted will be on display.

There are about 200 conference presentations, over three platforms:

- a Business Conference focusing on business strategies, market analysis, and business modelling

- a Technical Conference geared towards industry and applications

- a Scientific Conference – a forum for scientists to discuss the latest concepts as well as their research.

More details at www.lopec.com

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News