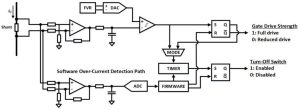

“The demonstrator can detect and interrupt fault currents in microseconds, 100 – 500 times faster than traditional mechanical approaches,” according to the company. “The fast response substantially reduces peak short-circuit currents from tens of kilo-amps to hundreds of amps, which can prevent a fault event from resulting in a hard failure.”

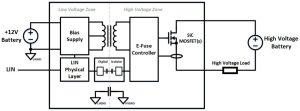

It “provides designers with a SiC-based solution to jump-start their development”, added Microchip v-p of SiC Clayton Pillion. “The solid-state design alleviates long-term reliability concerns about electromechanical devices because there is no degradation from mechanical shock, arcing or contact bounce.”

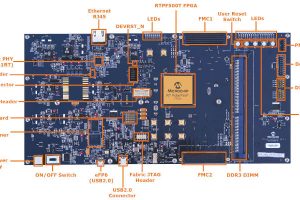

The demo board, which is described as an ‘auxiliary e-fuse design’ and is therefore not aimed at the main traction inverter, comes in six versions spanning 400 or 800V batteries, and 10, 20 or 30A circuits.

That said, “tt can be scaled to deliver power to the main traction inverter by using more parallel SiC devices”, Microchip told Electronics Weekly.

Current detection is staged, with a comparator-based purely hardware circuit detecting high current (100 – 200A, so short-circuits) faults in a microsecond. From there down to ~45A for more sophisticated control of currents, a slower firmware loop in a PIC microcontroller reacts in around a millisecond.

Below there, junction temperature estimation is used as a current-limiting metric to protect the e-fuse from over-heating. Estimation is based on a thermistor-based temperature measurement, the heatsink’s thermal capacity and drain current – modelled with a first-order infinite impulse response (IIR) digital filter.

A LIN bus is included for control and monitoring.

“The LIN interface enables the configuration of the over-current trip characteristics without the need to modify hardware components, and it also reports diagnostic status,” said Microchip. “With the e-fuse demonstrator’s resettable feature, designers can package an e-fuse in the vehicle without design-for-serviceability constraints.”

The board needs its own 9 – 16V supply (<100mA), and operates in ambients between -40 and +85°C.

Software support and debug comes via the MPLAB X IDE (integrated development environment), and there is a LIN serial analyser development tool for PCs.

There is an e-fuse demo product page, but much of the assocaited information is ‘on request’ only. This user guide has some good extra information

See Microchip on stand 108 in hall 7 at PCIM

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News