“In most cases, Presto creates a hardware solution that is built into the load board so that a standard tester could be used rather than having to buy and charge the customer for a highly specialised tester,” said the firm. “Test costs are based on the time that a tester is used, so the small additional costs of components on a load board is significantly more cost effective than moving to a higher feature or specialised tester.

An example is the addition of a current amplifier onto the load board, “a standard tester can now be used to measure currents as low as one nanoamp,” said Presto.

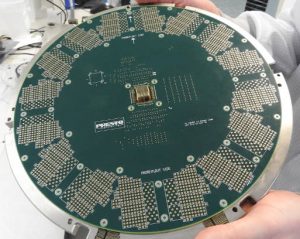

A load board to which active circuitry can be added to expand tester capability

A load board to which active circuitry can be added to expand tester capability

Another is when A customer needed 6.5GHz testing on a 6GHz tester. Rather than buy a 12GHz tester, the firm devised a frequency translator and integrated that into the load board so that the 6GHz tester could be used beyond its normal range.

In an example of a mechanical adaptation, the firm created an assembly using tiny motors for fine x and y alignment of a laser beam needed to stimulate individual photodiodes on a wafer when the existing wafer-shifting stepper motors proved to have insufficient resolution.

“Customers often come to us to solve their testing challenges,” said Presto sales v-p Martin Kingdon. “Frequently, the issue is that they are pushing the boundary of technology. This means that the manufacturers of test equipment have not created testers yet or, if they have, the testers are very expensive and specialised, as the need has not reached mainstream demand. Once developed, we can transfer and integrate these new test solutions into our high-volume production facilities in Asia.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News