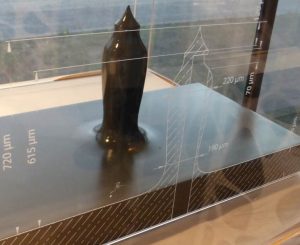

The idea is to allow injections without pain, with the final injecting short enough (720μm high, 220μm diameter) not to contact nerves (see photo of model).

Construction involves etching 80μm diameter holes 800μm deep from the back of the wafer, then performing a complicated series of etches from the wafer front to form the needle shapes, including sharp points. Each wafer yields 1,400 needles.

Front and rear etches are deliberately offset slightly sideways so that, combined with the needle shape, the exit hole emerges in the side of the needle.

“Unlike other intra-dermal delivery systems, DebioJect is made of hollow microneedles with a unique side protected delivery hole,” said Debiotech. “By placing the hole on the side of the needle at a precise depth, the skin can be punctured without coring and without removing any tissue. Because the skin remains intact above the side hole, leakage during injection is prevented and healing is improved. Furthermore, by injecting through the side hole, where the needle does not apply direct pressure on the tissue, liquid can diffuse more easily at a better define and controlled depth. This enables pain free injections of up to 0.5ml in only 5s.”

The needle was invented jointly by the Royal Institute of Technology Sweden, prototyped at the Swiss Federal Institute of Technology Luausanne, and productionised at Leti. Leti has also worked with CalTech to create neural probes by etching.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News