Inactivation here, said the company, is defined as the inability to multiply after exposure through damage to DNA and RNA.

“10ml of virus solutions [5 x 105 PFU/ml] in dishes were irradiated with 265nm UVC LED at different time points,” according to Stanley. “Infectious virus titers were determined by plaque assay on cells. Inactivation rate of SARS-CoV-2 is 99.9% or more when the UV Dose is 5.1mJ/cm2.”

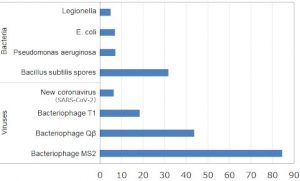

Time in seconds for the destruction of various infectious agents according to Stanley Electric

Time in seconds for the destruction of various infectious agents according to Stanley Electric

The company lists both pros and cons for optical anti-viral and anti-bacterial techniques:

Pros:

- no chemicals are used, so no need to wipe off or remove

- Effective against chlorine-resistant micro-organisms

- Does not produce UV-resistant bacteria

Cons:

- UV-C is hazardous to the human body and organisms

- UV-C can damage plastics and synthetic resins

- It cannot sterilise places where the light does not reach or in shadows

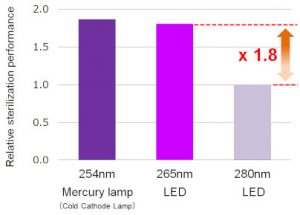

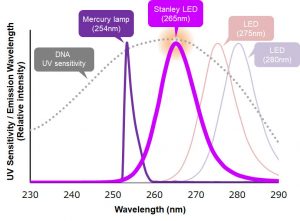

Stanley is pitching its 265nmUV-C devices against longer wavelength leds for inactivating infectous agents through DNA damage (Stanley graph right).

Stanley is pitching its 265nmUV-C devices against longer wavelength leds for inactivating infectous agents through DNA damage (Stanley graph right).

Very little of the Sun’s UV-C reaches the Earth’s surface and humans have little natural protection against it.

To emphasis the hazard point, Stanley issues this UV-C led safety warning: “Strong UV rays are irradiated from the UVC LED when lit which may damage your eyes. Please do not look directly at the LED when illuminated. If you must observe the product when lit, be sure to use protective glasses that block UV, as well as use protective masks and gloves to minimise the exposed areas on your skin.”

To emphasis the hazard point, Stanley issues this UV-C led safety warning: “Strong UV rays are irradiated from the UVC LED when lit which may damage your eyes. Please do not look directly at the LED when illuminated. If you must observe the product when lit, be sure to use protective glasses that block UV, as well as use protective masks and gloves to minimise the exposed areas on your skin.”

The company owns the whole of its AlN led production chain, having bought AlN substrate maker Hexatech in march. Its UV-C leds entered mass production in July. There are binned with 25, 30, 35 or 50mW outputs, all driven at 440mA (6.9Vf), and come in a 3.5 x 3.5 x 2.24mm package.

Electricity to UV conversion is 2 to 3%, compared with 15 to 20% for the 254nm CCFL UV-C lamps the company also makes – the CCFLs require high-voltage drive while the leds need heatsinking.

The 1p-BH evaluation kit (right) comes with a 50x50mm heatsink

The 1p-BH evaluation kit (right) comes with a 50x50mm heatsink

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News