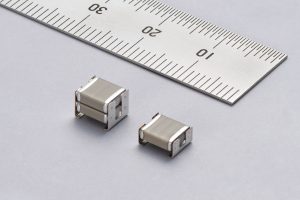

The tags can be fitted to metallic and non-metallic surfaces, perfect for use on small items.

To avoid any risk of contamination during the drug filling operations, they can also be embedded into the product, such as pre-filled syringes, vials and cartridges.

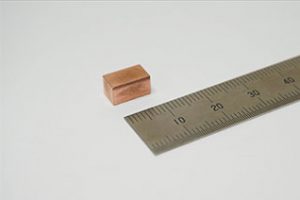

Murata integrated an antenna in a multilayer ceramic substrate to create a small and robust RFID tag capable of automatic identification and bulk reading of over 400units/min for high throughput efficiency.

This capability allows real-time identification at full production speeds, preventing any mix-up during drug filling operations. The RFID tags also provide item-level serialization, thus limiting batch segregation should a defect be found in the aftermarket.

“New regulations for product traceability and quality control in the production line from health authorities like the FDA (Food and Drug Administration) and USP (US Pharmacopeia) are driving the healthcare industry to identify and authenticate individual products from the cradle to the grave,” says Teppei Miura, General Manager, Murata ID Solutions. “The small RAIN RFID tag is perfect for identifying products, such as pre-filled vials and syringes and single-use injectors, during high-speed production processes as well as providing traceability for authentication in the aftermarket.”

Conventional tracking of pre-filled vials and syringes requires a QR code as an applied label or printed directly onto the product’s surface. Unlike RFID tags, which support bulk reading, QR codes are read individually, slowing down production. As these biochemical products require strict temperature control, condensation can also make it difficult to scan the QR code. Retrofit labels also pose a potential risk of contamination during the filling processes.

Embedding the RAIN RFID tag directly into the component of the vial and syringe overcomes these challenges with no risk of contamination or impact on visual inspection; it also takes out the process step of applying the QR code. And, as all the pertinent information remains with the item, manual input errors are eliminated.

In the aftermarket, benefits of using RAIN RFID tags include navigation by users, such as instruction for use, and third-party drug and counterfeit drug prevention. For rechargeable insulin injectors, the RFID tags can also be used as part of the connected ecosystem to send usage data to the cloud for patient monitoring purposes.

For more information, see here.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News