IO-Link is a short-range (<20m) point-to-point industrial bus developed to connect sensors and actuators to a local hub, from which the data is transferred to a remote PLC (programmable logic controller) via Ethernet or other long-range field bus.

“The IO-Link interface allows every IO-Link sensor, actuator or IO expansion module to be interchangeable to a standard hardware interface. It also provides software-defined performance parameters and selectable analogue input or output performance modes,” according to Maxim.

Two of the new parts are:

- MAX22000 software-configurable analogue IO

±36V protection on all analogue IO

24bit ADC input

18bit DAC output

±10V voltage mode I or O

±20mA current mode I or O

programmable gain amplifier (supports 2 or 4 wire resistance temperature (RTD) or thermocouple) - MAX22515 single channel IO-Link transceiver

Integrated ±1.2kV/500Ω surge-protection

selectable 3.3V or 5V LDO

2.2Ω or 2.65Ω (typ) C/Q driver

2.5 x 2mm WLP package

Combining these is the MAXREFDES177# reference design (photo above)

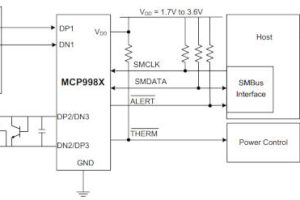

“MAXREFDES177# demonstrates a fully software-configurable analogue IO module,” said Maxim. “The analogue side is fully isolated from the IO-Link side with the MAX14483 digital data isolator and an isolated power supply derived from the L+ 24V supply from the IO-Link master connection.”

It uses an industry-standard M12 connector with a 4-wire IO-Link cable, and the analogue/field side has a 4-way PCB terminal block. The PCB is 61 x 25mm.

Configurable analogue modes include: ±10V input, ±20mA input, ±10V output or ±20mA output across the AIO and GND terminals. linear range is 105% and full-scale range is 125% nominal.

“The accuracy is as good as 0.1% over a ±50°C temperature variation,” said Maxim. “The other two terminals can be configured to measure temperature using a standard device such as a PT100 or PT1000 RTD. These terminals interface to the integrated PGA in the MAX22000.”

An Atmel ATSAM MCU interfaces between MAX22000 and MAX22515 IO-Link device transceiver. The reference design uses the TMG TE (Technologie Management Gruppe Technologie und Engineering) IO-Link stack to communicate to any IO-Link version 1.1-compliant master.

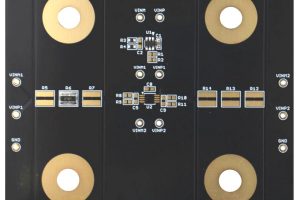

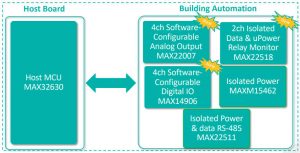

At the same time as the chips and reference design, Maxim announced a second generation of its Go-IO software-configurable IO standard for factory and building automation (photo right above host board).

The company has previously physically shrunk its industrial IO with each new generation – from ‘Micro PLC’ (540cm3) in 2014, through Pocket IO (167cm3)to the original Go-IO in 2018, but Gen 2 retains the 12cm3 PCB format of its predecessor. “12cm3 is already very small, it’s two thirds of a credit card” said Maxim’s ghghg. “, we might even make it a little larger to fit [extra] features on if customers want them.”

Along side the Go-IO gen2 format, the company announced reference designs for building automation (left) and factory automation.

Along side the Go-IO gen2 format, the company announced reference designs for building automation (left) and factory automation.

The MAXREFDES177# reference design (top of article) product page is here

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News