There is currently a global chip shortage, prompted by the Covid-19 pandemic and the consequent surge in demand for electronics. The growth of IoT devices has also certainly played its part and is putting increasing pressure on the stock of chips.

Despite the easing of the pandemic, there is no sign of this shortage coming to an end any time soon. In May last year, Jim Whitehurst, the president of IBM, commented that the global chip shortage may last a couple more years. These conditions are making it more important that electronics devices are durable to avoid the need to repair and replace them frequently – and, with every replacement, reduce the store of available chips further.

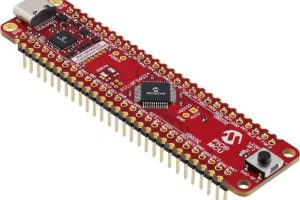

The growth of the IoT, combined with the current chip shortage, calls for manufacturers to add the right protection to a device in the factory.

Chip shortages

The extent of the global chip shortage means that it is looking likely that millions of people will be affected. As the demand is bigger than the supply, a significant number of companies are feeling the pinch: car makers; smartphone and computer manufacturers; television and appliance producers. Nobody is exempt – some of the biggest names have been affected to some degree and at some time – Apple, BMW, General Motors, LG, Samsung, Sony, Tesla and Whirlpool to name a few.

Retailers may feel the effects of chip shortages and consumers may find some products in short supply. The supply shortfall might also make technology products more expensive, with sellers on Amazon or eBay inflating the prices, with consumers once again feeling the impact.

Increasing lifespans

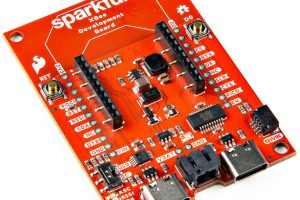

Juniper Research projected that the number of IoT devices would reach 46 billion in 2021, a 200% increase compared to 2016. Every one of these devices has a chip of some sort within it and will be exposed to environmental threats over time, whether they are located outdoors or even indoors, through temperature swings, air conditioning and moisture, for example. If those devices start to corrode, organisations will not be able to afford to keep sending engineers to fix them because the cost will be prohibitive.

The European Environmental Agency has found that the lifespan of electronics is at least 2.3 years shorter than their designed or desired lifetimes. The global chip shortage has further highlighted the importance of increasing the actual lifetime use of these products. One of the most significant risks to the integrity and longevity of products is liquid damage. Five in every six (83%) manufacturers would expect their electronic products to fail within a year without liquid protection.

Consequently, to improve the lifespan of electronic devices manufacturers should require a number of different levels of liquid protection, from splash resistance to submersible devices. This is essential for devices being fit for purpose and lasting longer. Nanocoating provides value for manufacturers. The initial investment significantly extends the product’s lifetime to keep it in use by the customer for longer, providing cost savings from fewer returns as well as acting to strengthen the brand image and reducing e-waste.

Fortunately, solutions such as plasma nanocoatings can be seamlessly integrated within manufacturers’ supply chains or overall manufacturing processes to ensure that liquid protection is built into devices at the design stage.

Sustainability

Building reliability and sustainability in at the design stage is important to address environmental concerns too. Extensive damage can cause vital components within a device to suffer from corrosion, making them unusable and ultimately unrepairable, adding to landfill and damaging the environment.

Producing devices with a longer lifespan will help manufacturers reduce the need for repairs and the demand for spare parts, including chips, assisting in the reduction of their environmental footprint. The partnership between liquid protection suppliers and manufacturers will successfully reduce waste and ensure the sustainability of their liquid-protected electronic products.

The global chip shortage has served to highlight the need for devices to be built to last to reduce the need to replace and alleviate demand for chips. Building liquid protection into devices from the outset will not only assist with this, but by ensuring the longevity of devices, manufacturers will increase the sustainability of their products and allow consumers to get more from their devices.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News