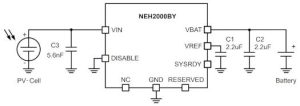

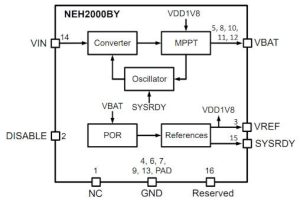

Inside the IC, called NEH2000BY, power conversion is thorough a voltage-doubling capacitive dc-dc converter, controlled by an algorithm that adjusts the converter with the aim of hitting its efficiency target with varying ambient light on different kinds of PV cells feeding power to a variety of batteries. When light levels change, adjustment is said to be in under a second.

Inside the IC, called NEH2000BY, power conversion is thorough a voltage-doubling capacitive dc-dc converter, controlled by an algorithm that adjusts the converter with the aim of hitting its efficiency target with varying ambient light on different kinds of PV cells feeding power to a variety of batteries. When light levels change, adjustment is said to be in under a second.

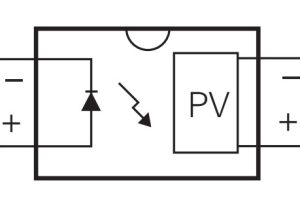

Due to the typical shape of photovoltaic loading curves, and the voltage multiplier’s characteristics, picking a PV cell with an open-circuit voltage of 0.69 time the battery voltage will give the algorithm the best chance of hitting its target, said Nexperia, which broadens this to between 0.5x and 0.8x for reasonable performance.

Electronics Weekly has asked for more detail on its optimisation algorithm and its limitations as the data sheet it not entirely clear – so watch this space. So far, it has responded that its power tracking technique “actually measures the power accurately”.

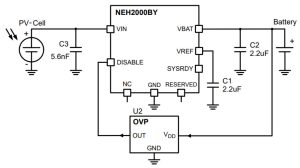

It can operate with rechargeable batteries between 2.5 and 4.5V, and run with a battery as low as 2V, and the cells output can vary up to the battery voltage – although more than 2V will damage the IC if the battery is not connected. “To prevent battery charging directly from the PV cell, take care that open-circuit voltage is lower than Vbatt plus a diode voltage,” said the company. Optimisation is “for photovoltaic harvesters, but integrates with any other harvester that complies with its input voltage range”.

Start-up needs at least 1.65V from the cell as well as 2.5V from the battery. Any charge qualification for the battery, such as over-voltage (right) or temperature, needs to be external, feeding back into the IC’s disable pad.

Although minimum input power is nominally 35µW, Nexperia said: “NEH2000BY can be configured for operation starting at 10μW input power. In this case, the power range shifts down by about a factor of two”, but gives no further details in the data sheet.

Operation is over -40 to +85°C and packaging is 3 x 3mm 16 pad plastic QFP – the compnay claims total board area, including the three necessary external capacitors, can be 12mm2.

Applications are foreseen in wireless IoT nodes, wearable smart tags and electronic shelf labels.

For the future? “The next version will have a significantly larger boosting factor,” Nexperia told Electronics Weekly. “For most common applications however, 2x is sufficient.”

—

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News