What sort of transistor is it?

“We don’t go into details of the device,” Power Integrations’ director of automotive business Peter Vaughan told Electronics Weekly. “It looks like a mosfet, so we call it a mosfet.” The control IC within the system-in-package is the same as the silicon mosfet versions, he added.

Electronics Weekly has subsequently asked Power Integrations if the ‘mosfet’ is really a cascode pair of a silicon carbide jfet and a silicon mosfet – the arrangement advocated by device maker UnitedSiC, for example.

Previously, the same converter range in 750V or 900V form could be used with 1,200V batteries by cascoding an external high-voltage silicon mosfet on the primary side. The company has application notes for this, branding the arrangement StackFet.

The new part saves the eight components in the cascode circuit, and “the customer does not have to do high-voltage testing on their cascode,” said Vaughan.

As an aside, Power Integrations has used GaN transistors in some models of its other InnoSwitch3 families (-Pro, -CP, -EP, -PD and -MX), but no so far to its -AQ automotive family, nor its -CE family.

Proposed as safety converters – power supplies that keep in-vehicle electronics systems working during electrical anomalies – the devices have a very wide operating range. “Most exciting is the opportunity to simplify the emergency power supply for the main traction inverter, which may be called upon at a moment’s notice to operate from any voltage between 30Vs and 1,000V,” said Vaughan.

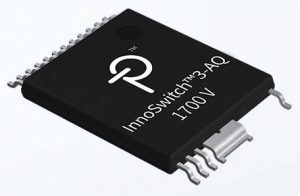

There are two 1.7kV Innoswitch3-AQ parts: the 50W INN3947CQ and the 70W INN3949CQ. Two reference designs (right) have been released:

There are two 1.7kV Innoswitch3-AQ parts: the 50W INN3947CQ and the 70W INN3949CQ. Two reference designs (right) have been released:

- DER-913Q for the INN3947CQ – 40 to 1,000V input, 24V 35W out

- RDR-919Q for the INN3949CQ – 50 to 1,000V input, 24V 60W out

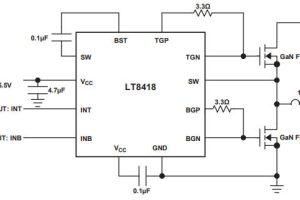

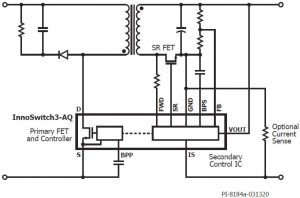

The parts are secondary-side regulated (below left) with the company’s in-package ‘FluxLink’ inductive coupling completing the feedback loop and avoiding the need for an opto-coupler. Parts are 100% hi-pot tested to 4.5 kV in production.

Output regulation can be ±3%, and synchronous rectification on the secondary side allows further secondary windings (with diode rectification) to produce auxiliary voltages with reasonable regulation without being directly regulated, said Vaughan.

Converter efficiency can reach above 90%, and no-load consumption can be as little as 15mW.

Protections include: input under-voltage, output over-voltage and over-current limiting.

Industrial application are also foreseen, in motor drives, battery storage and metering, and with renewables.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News