Several lithium-ion chemistries, such as lithium-iron phosphate, lithium-manganese, and lithium-titanate are good EV/HEV candidates. Unlike Lithium-cobalt cells, these lithium chemistries are thermally stable and offer low equivalent series resistance (ESR) to support high current. If carefully managed, these batteries could last 10 to 15 years.

Need for battery management

Li-Ion cells provide a typical operating potential of 4V at full charge and 2V at full discharge. To minimise the level of current, which allows for smaller, lighter and less expensive cables and motors, the EV/HEV battery pack is typically stacked as a group of 100 to 200 series-connected cells.

Even at these high voltages, the peak charge and discharge currents of EV/HEV battery stacks can exceed 200A.

Charging any Li-Ion cell to 100% of its state-of-charge (SOC) or discharging to 0% SOC will degrade its capacity. Therefore, only a portion of a cell’s capacity can be used if the battery must have a long life. With very accurate control of the state of charge of each Li-Ion cell, battery pack capacity can be maximised while its degradation is minimised. However, controlling hundreds of series-connected cells is quite challenging.

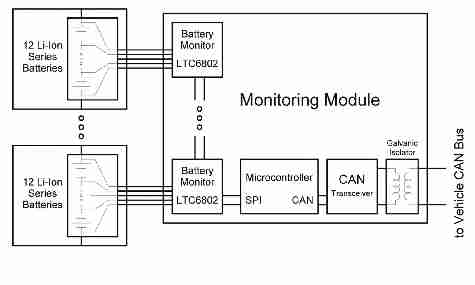

The primary task of battery management system (BMS) electronics is to quickly and accurately measure each battery cell’s voltage. This requires extracting relatively small differential voltages from very high common mode voltages.

This is accomplished by placing high-quality, high common-mode difference amplifiers at each cell to provide translated signals, ready to be digitised by an analogue-to-digital converter (ADC).

Battery management electronics should also incorporate a number of other features. For example, the state-of-charge determination requires temperature and current measurements. For practicality, the BMS electronics should be powered directly from the battery sense connections.

For safety, the interface between data acquisition and host processor should be galvanically isolated. Finally, it is important for HEV and EV batteries to maintain cell balance.

Cell balancing is a critical function for high-powered battery packs because a long series of individual cells is only as reliable as the weakest cell. It is critical that the charge level of all cells does not stray outside the recommended SOC range. For this reason, the designer must design for long periods of battery pack inactivity, prior to installation and during vehicle transport or storage. To ensure that the batteries cannot be over-discharged during inactivity, the BMS idle power must be significantly less than the self-discharge of the battery cells.

More importantly, the idle current along the battery string must be well matched to ensure that batteries do not become unbalanced during storage. Once placed into operation, the batteries will experience high charge and discharge currents. In this situation, the charge level of each cell must be actively balanced to derive maximum pack energy and lifetime.

A simple and cost-effective technique for cell balancing, commonly used in EV/HEV designs today, is passive-balancing.

With passive-balancing, a resistor is placed across a cell when its state of charge exceeds that of its neighbours. It should be noted, however, that passive-balancing wastes energy and can generate considerable heat. Future generations of battery management systems will likely incorporate active balancing, where a storage element is used to move charge between cells.

Other design considerations

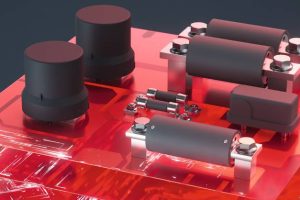

The physical size and weight of a large battery cell array has practical implications for its serviceability and distribution. It is also important to consider that significant data is generated by continuously monitoring every battery cell. For these reasons, a module approach may be suitable where the battery management task is divided into subsets and a local processor can be placed at the module level. The module approach also provides a common platform for multiple designs. The minimum size of the module will likely be dictated by the additional wiring harness cost and complexity, as the number of modules is increased.

Connecting a large high-voltage battery stack to electronics presents another significant design challenge. The battery to electronics interface typically consists of many contacts, over many individual connectors.

Since the data acquisition electronics are typically unpowered when connected to the batteries and connections can occur randomly, the BMS must be designed for hot-plugging. To prevent damage from surge currents, external protection is prudent. As an example, standard Zener diodes across each cell input will automatically distribute safe voltages across missing inputs as random contacts are made.

After years of effort and steady progress, high-energy battery systems will soon be practical for everyday use, especially as part of the electric and hybrid electric vehicle.

Basic topology of a high cell count EV/HEV module

Author Greg Zimmer is product marketing engineer at Linear Technology

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News