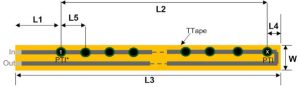

Branded TTape, it detects local over-heating via thermally sensitive spots spaced along its length, all connected in series. The spots are positive temperature coefficient thermistors.

“Distinguishing itself from NTCs [negative temperature coefficient thermistors], the profound advantage of localised cell overheating detection ensures quicker alerts to the battery management system,” claimed company product manager Tong Kiang Poo. “No calibration or temperature look-up tables are required, and only one MCU input needed.”

It is designed to be used as the lower part of a grounded potentiometer connected to a microcontroller input pin, with a resistor (100 or 200kΩ) connetected to the positive rail completing the circuit. 10 or more bits of resolution is specified for the ADC behind the MCU pin.

It is designed to be used as the lower part of a grounded potentiometer connected to a microcontroller input pin, with a resistor (100 or 200kΩ) connetected to the positive rail completing the circuit. 10 or more bits of resolution is specified for the ADC behind the MCU pin.

Tripping occurs when part of the tape reaches 58±3°C, and it resets when it drops below 42±3°C. These numbers depend on a number of caveats – see the data sheet for more details.

Response time is said to be under one second.

Operating temperature range is -40 to +85°C and, very unusually, according to the data sheet storage range is less than that at -40 to +55°C.

Absolute maximums on the tape are 6V and 6mA, and dielectric withstanding is to 2.5kV (MIL-STD-202 method 301).

For installation, one surface is self-adhesive and compatible with compatible with metal, polyamide, PET and polyimide surfaces. Termination is by soldering to wires, and the company recommends protecting these joints with a layer of polyimide dielectric tape.

A 10 spot sample tape 337mm long and 10mm wide is available, but many applications are expected to need custom designs where the limits are: up to 1m long, up to 50 sensing spots, and 8 or 10mm wide. A stitching option allows tapes of up to 8m long to be delivered.

Thickness is not specified, but the company said: “The extremely thin design of TTape makes it ideal for conformal installations.”

Use is also expected in large energy storage batteries and power tools.

Find the TTape product page here, and its data sheet here – which is rather short and really needs to be read with this application note

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News