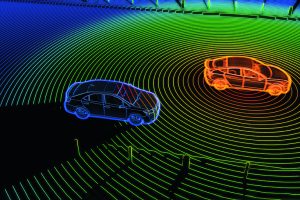

By utilizing the active alignment assembly process to achieve superior camera focus and produce high-resolution images, these camera modules play an essential part in the advanced driver assistance system (ADAS), which plays an important role in ensuring the safety of drivers, passengers, and pedestrians.

Throughout the entirety of the vehicle’s lifetime, these modules need to function with high resolution and deliver exceptional reliability in challenging environments. ADAS cameras can only tolerate miniscule changes in the positions of its optical components, and the adhesive used plays a major role in meeting these precise positioning requirements. In order to successfully assemble these camera modules, the adhesives that are used need to have a high level of adhesion to surfaces while also having low and predictable shrinkage.

When choosing an adhesive that is appropriate for the assembly of ADAS camera modules, other variables to take into consideration include environmental responsibility and worker safety. The adhesive must not contain any substances that are carcinogenic, mutagenic, or teratogenic (CMT), nor can it make use of any materials that are listed as substances of very high concern (SVHC) in the REACH regulation of the European Union.

Henkel continues to develop new adhesives for camera module assembly. These adhesive solutions are being developed with the express purpose of satisfying the strict requirements of the automotive industry.

Henkel’s Active Alignment Adhesives ensure reliable, fast bonding while achieving optimal lens alignment in these safety-critical modules, representing the next generation of highly reliable and dimensionally stable ADAS camera module adhesives. These innovative adhesives are fully compliant with EU REACH and do not contain any CMT or SVHC substances, nor do they use any toxic ingredients. Due to the fact that they have a low CTE across a broad temperature range, they maintain remarkable dimensional stability even when exposed to harsh environmental conditions. Because of improvements in dimensional stability, camera sensors are now able to take readings that are reliable and accurate. They cure very quickly, within a few seconds of UV exposure, and unlike their free-radical counterparts, they are not oxygen inhibited. They have a viscosity profile that makes for easy dispensing and very good adhesion to a wide variety of substrates, including plastics, which makes them the ideal choice for any premium camera module that is used in ADAS applications.

Even though these ground-breaking adhesive solutions are excellent options for manufacturing high-quality camera modules, we are constantly working to improve adhesive performance. Our most recent ground-breaking innovation, which will be released very soon, will completely transform the way that ADAS camera modules are assembled. This revolutionary one-step UV-cure camera module assembly adhesive will provide a number of benefits, including an increase in the output of camera assembly lines, a streamlined assembly procedure, a significant reduction in the amount of energy that is required for manufacturing, and an increase in the level of sustainability that is provided.

Customers who work closely with Henkel throughout the entirety of the product design process will be in the best position to take advantage of forthcoming advancements in adhesive technology and incorporate them into their products as well as their manufacturing processes. In our most recent whitepaper, you’ll find more information about the reliable, fast bonding Active Alignment Adhesive solutions that we offer for the assembly of high-resolution ADAS camera modules in automobiles, along with what innovations can be expected in the future that will further improve the performance and efficiency of these adhesives.

By Andreas Niegemeier, Rime Ganfoud, Stieven Josso, Shingo Tsuno, Takayuki Kanno

For More Information Download Our White Paper Now:

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News