In semiconductor and electronic equipment manufacture, the quality control (QC) process is essential to ensuring defect-free products that meet specifications and comply with international standards. Here, manufacturers rely heavily on industrial microscopes to ensure a thorough and reliable examination.

While the visual inspection needed for QC can be costly and time-consuming, advances in microscope software are helping to optimize product inspection. The PRECiV™ software from Olympus* has been designed to speed-up detection – maximizing time and budget – while simultaneously standardizing microscope operation to improve the repeatability of results.

At the heart of the PRECiV™ software is its user-friendly, fully-customizable and easy-to-navigate interface providing integrated control of compatible microscopes, motorized nosepieces, and microscope cameras, including short-wave infrared (SWIR) technology.

For new and experienced users alike, image acquisition and data recording are made quick and simple through an intuitive navigation tab and large, clearly-labeled buttons. Straightforward acquisition is complemented by a range of live enhancement features such as high dynamic range (HDR) adjustment and halation removal, allowing QC operators to expand their imaging and detection capabilities.

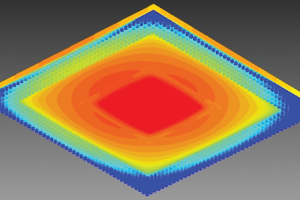

One of the most attractive features of the PRECiV software is the ability to capture automatically focused, panoramic images when used in conjunction with a motorized microscope. Using extended focal image (EFI) and/or panorama modes, PRECiV enables you to stitch together multiple images (longitudinally or latitudinally) to create one all-in-focus image. These large, high-quality images aid the examination of large semiconductor wafers and electronic components.

As well as the ability to acquire and analyze high-quality images, the PRECiV software offers features that help standardize and improve the efficiency of your inspection process. For example, personalized manual measurements and workflow steps can be defined to generate automatic options and provide guidance for improved repeatability. Additionally, settings – such as measurement parameters, imaging condition, and access rights – can be shared across the network helping to improve standardization.

Finally, PRECiV software has been designed to improve systematic compliance across multiple users. Automated calibration checking ensures all microscope calibrations and measurements are conducted in accordance with international fabrication regulations, avoiding operator errors. Additionally, all measurement analyses can be exported to an excel report and guidance is provided throughout the workflow to help users stay compliant with international standards.

*Olympus’ Scientific Solutions business became a wholly-owned subsidiary, on 1st April 2022.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News