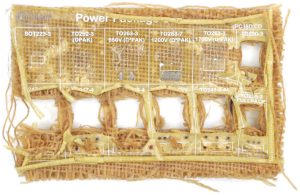

The substrate, branded Soluboard, is from UK start-up Jiva Materials, which claims that it would result in a 60% reduction in carbon emissions compared with FR-4, saving 10.5kg of carbon and 620g of plastic per square meter of PCB.

Made from undisclosed natural fibres and a halogen-free polymer, the board is said to be “flame-retardant to the same extent as other market leading PCB substrates”, according to Jiva. When the board is no longer needed, it is dropped into hot water and degrades into “compostable organic material” plus the components.

“We are actively researching the reusability of discrete power devices at the end of their service life,” said Infineon product manager Andreas Kopp.

Just add hot water

Is Soluboard susceptible before it is recycled?

“Jiva is in the process of ensuring that Soluboard is compatible with aqueous PCB fabrication processes,” according to Jiva. It “is also engineering Soluboard to be resistant to high humidity environments”.

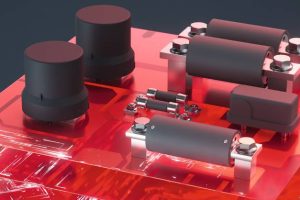

So far, Infineon has produced three demo boards using the material, including one with including portfolio, including one with components specifically for refrigerators. In total, 500 units have been made loaded with power discretes.

Based in Hampshire, Jiva intends to license the manufacture of Soluboard. Its website, and Soluboard, can be found here

The savings figures above are based on estimating the carbon footprint of one square metre of Soluboard at 7.1kg and FR-4 at 17.7kg.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News