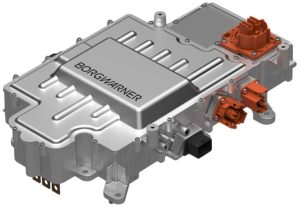

“STMicroelectronics will supply BorgWarner with third-generation 750V silicon carbide power mosfet die for their proprietary Viper-based power module,” according to ST. “This power module is used in BorgWarner’s traction inverter platforms for several current and future Volvo Cars electric vehicles.”

It continued that the two companies collaborated to match ST’s SiC mosfet die with BorgWarner’s Viper power switch – Viper is a power module, used in multiples within an inverter, with more in higher power inverters.

Such is the demand foreseen for SiC power components, that companies up and down the supply chain have signed multiple deals to ensure continuity of supply.

“This collaboration [with ST and BorgWarner] will strengthen our increased vertical integration and our control of critical components,” said Volvo COO Javier Varela.

ST’s high-volume SiC products are manufactured in its own Italian and Singapore fabs, with back-end packaging and testing at its facilities in Morocco and China.

In October last year, ST announced it would build a SiC substrate production line in Catania Sicily, where is has power semiconductor research, development and manufacturing.

In April this year, car component supplier ZF signed ST up to supply, from 2025 “double-digit millions of third generation silicon carbide mosfet devices”, said ST. They are for ZF’s modular traction inverter, going into series production in 2025 for a “European car manufacturer whose production start is planned for 2025”.

“Our order book in electromobility until 2030 now amounts to more than €30bn,” said ZF board member Stephan von Schuckmann at the time. “For this volume, we need several reliable suppliers for silicon carbide devices.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News