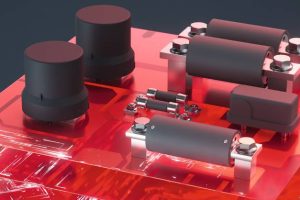

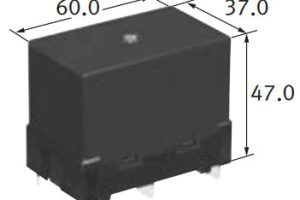

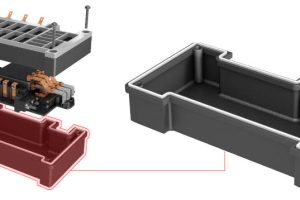

The 48V electric motor that operates the steering rack was developed in-house along with the rest of the mechanical system and the control unit. All of it is made in Cambridgeshire UK, including PCB manufacture and assembly.

There are no off-the-shelf units, instead “Titan’s approach is to work with the customer’s design team to deliver the performance characteristics that are required”, said company technical director Paul Wilkinson. “The system is a tune-able tool-box, enabling lower-volume next-gen vehicle makers to calibrate steering responses exactly to application, resulting in just the right feel for the driver. Under one roof, we can take a design from a clean sheet of paper to full industrialisation.”

There are no off-the-shelf units, instead “Titan’s approach is to work with the customer’s design team to deliver the performance characteristics that are required”, said company technical director Paul Wilkinson. “The system is a tune-able tool-box, enabling lower-volume next-gen vehicle makers to calibrate steering responses exactly to application, resulting in just the right feel for the driver. Under one roof, we can take a design from a clean sheet of paper to full industrialisation.”

Expected volume are 100 unit/month down to one-offs.

The company has been operating for 60 years, developing racing cars in the 1960s, and now supplying the automotive industry with steering systems, drive-trains, chassis and engines. Control systems can be developed under ISO 26262 to ASIL-D. It has “supplied systems for iconic sports cars and top-level motor sport teams, as well as the latest electric commercial vehicles”.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News