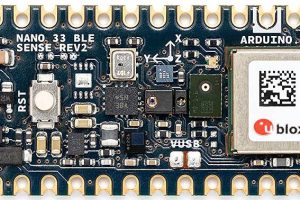

Built around an STM32H747XI microcontroller, internal processing comes from two cores: a 480MHz Arm Cortex-M7 and a 240MHx Cortex-M4.

It is essentially DIN-rail relay output and sensor input module, with four 10A 250V (400Vmax) relays for load switching (4 x 2.3kW), and eight input that can be configured as digital or 0-10V analogue.

For more industrial electronics stories see here: Markets.Industrial

For a choice of field interface, there are three versions:

- Opta Lite (AFX00003) Ethernet (Modbus TCP) and USB-C programming ports

- Opta RS485 (AFX00001) adds RS485 half duplex interface (Modbus RTU)

- Opta WiFi (AFX00002) further adds Wi-Fi and Bluetooth Low Energy

“Its dual-core MCU allows users to perform real-time control, monitoring and implement predictive maintenance applications,” according to Arduino. “Secure and durable by design, it supports over-the-air firmware updates and ensures data security from the hardware to the Cloud thanks to the onboard secure element and X.509 Standard compliance.” Application control is “via real-time dashboards combined with the Arduino Cloud or third-party services”.

Software development is typically Arduino, via Arduino sketches, tutorials and libraries, and support for standard IEC 61131-3 PLC languages it scheduled – through the Arduino PLC IDE, which currently supports the company’s Portenta industrial control boards.

Power is 12 – 24Vdc

“Opta can be combined with load cells or vision systems to manage manufacturing flow, ensuring boxes are properly filled as they move along conveyor belts,” said the company. “It can perform clock synchronization via Network Time Protocol and automatically print time information on product labels or packaging. It can enable real-time monitoring, locally via a human-machine interface or remotely by connecting to the Arduino Cloud, using custom dashboards to ensure manufacturing processes run smoothly. You can even prevent issues by implementing predictive maintenance, thanks to Opta’s computing power and machine learning algorithms, able to detect anomalies.”

The Arduino Opta product page can be found here and Arduino PLC IDE here.

See also: Industrial SBC for AMD Ryzen Embedded R2000 processors

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News